| Chip Common Mode Filter-CM Series |

|

|

|

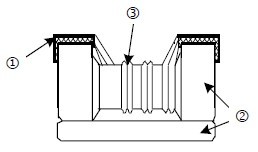

| ① |

Terminal |

② |

Ferrite |

③ |

Enamel-insulated Wire |

|

|

|

| ■Features |

-Small chip inductor with ferrite core and two line types

wire wound

-Highly effective in noise suppression High

common-mode impedance at noise band and low

differential-mode impedance at signal band

-Low differential-mode impedance with high coupling

factor. There is almost no distortion on high-speed

signal.

-Operating temperature -40°C~85°C |

|

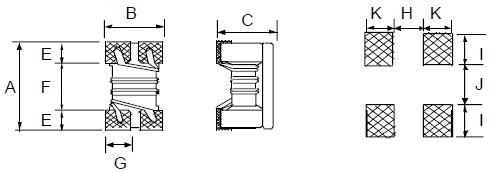

| ■Dimensions |

|

|

|

| ■Applications |

-EMI Radiation Noise Suppression for Any Electronic

Device

-USB Line for Personal Computers and Peripheral

-IEEE 1394 Line for Personal Computers, DVC, STB

-LCD Panels. Low-Voltage Differential Signal (LVDS) |

|

Unit: mm |

| Type |

Size

(Inch) |

A |

B |

C |

E |

F |

G |

H |

I |

J |

K |

Weight

(g)

(1000pcs) |

| CMH05 |

0805 |

2.0±0.2 |

1.2±0.2 |

1.2±0.2 |

0.45 |

1.2 |

0.4 |

0.8 |

0.4 |

0.4 |

0.90 |

19 |

| CMH06 |

1206 |

3.2±0.2 |

1.6±0.2 |

1.8±0.2 |

0.60 |

2.0 |

0.6 |

1.6 |

0.6 |

0.4 |

1.05 |

53.3 |

|

|

|

|

| ■Part Numbering |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shielding

Type |

H: Shielding |

|

|

| Dimensions |

05: 0805

06: 1206 |

|

|

Impedance

Tolerance |

M: ±20% |

|

|

Packaging

Code |

T: Taping Reel

B: Bulk |

|

|

| Impedance |

900: 90Ω

121: 120Ω

102: 1000Ω

222: 2200Ω |

|

|

|

| ■Standard Electrical Specifications |

|

|

Impedance

(Ω) |

Tolerance |

Test

Condition

(MHz) |

DCR

(Ω) max. |

IDC

(mA) max. |

Rated Voltage

Vdc (V) |

Withstanding

Voltage Vdc

(V |

Insulation

Resistance

(MΩ) min. |

| 67 |

±20% |

100 |

0.25 |

400 |

50 |

125 |

10 |

| 90 |

±20% |

100 |

0.35 |

330 |

50 |

125 |

10 |

| 120 |

±20% |

100 |

0.30 |

370 |

50 |

125 |

10 |

| 180 |

±20% |

100 |

0.35 |

330 |

50 |

125 |

10 |

| 200 |

±20% |

100 |

0.35 |

330 |

50 |

125 |

10 |

| 260 |

±20% |

100 |

0.40 |

300 |

50 |

125 |

10 |

| 360 |

±20% |

100 |

0.40 |

280 |

50 |

125 |

10 |

| 370 |

±20% |

100 |

0.40 |

280 |

50 |

125 |

10 |

|

|

|

Impedance

(Ω) |

Tolerance |

Test

Condition

(MHz) |

DCR

(Ω) max. |

IDC

(mA) max. |

Rated Voltage

Vdc (V) |

Withstanding

Voltage Vdc

(V) |

Insulation

Resistance

(MΩ) min. |

| 90 |

±20% |

100 |

0.30 |

370 |

50 |

125 |

10 |

| 160 |

±20% |

100 |

0.40 |

340 |

50 |

125 |

10 |

| 260 |

±20% |

100 |

0.50 |

310 |

50 |

125 |

10 |

| 600 |

±20% |

100 |

0.80 |

260 |

50 |

125 |

10 |

| 1000 |

±20% |

100 |

1.00 |

230 |

50 |

125 |

10 |

| 2200 |

±20% |

100 |

1.20 |

200 |

50 |

125 |

10 |

|

|

| ■Characteristics (Impedance vs. Frequency)-CMH05 |

|

|

|

|

|

| ■Characteristics (Impedance vs. Frequency)-C06 |

|

|

|

|

| ■Environmental Characteristics |

|

| Electrical Performance Test |

| Items |

Requirement |

Test Conditions / Test Methods |

| Impedance |

Refer to standard electrical

characteristic spec.

Component should not be damaged |

LCR Meter HP 4291B |

| DC Resistance DCR |

Micro-Ohm meter (GOM-801G) |

Withstand Voltage (VDC)

Rated Voltage (VDC) |

Test Voltage: 2.5 Times Rated Voltage

Testing Time: 60 seconds

Charge Current: 0.5mA

Test Voltage: Rated Voltage

Testing Time: 1 to 5 seconds

Charge Current: 1mA |

| Insulation Resistance (I.R) |

Charge Current: 1minute

10M ohm min. |

|

| Mechanical Performance Test |

| Items |

Requirement |

Test Conditions / Test Methods |

Component Adhesion

(Push Test) |

Base: 0805≧2 Lbs

Cover: 0805≧1 Lbs

Base: 1206≧4 Lbs

Cover: 1206≧2 Lbs |

The component should be soldered (232°C ± 5°C for 10 sec.) to

tinned copper substrate

Applied force gauge to the side of component It must withstand

force of 2 or 4 pounds without failure of the component. |

Drop

Solderability |

Component should not be damaged

The terminal should at least be 90%

covered with solder |

Dropping chip by each side and corner. Drop 10 times in total

Drop height: 100 cm

Drop weight: 125 g

The component shall be dipped in a melted solder bath at 245

±5°C for 3 seconds |

Vibration Test (Low Frequency) |

Component should not be damaged |

1. Amplitude: 1.5 m/m

2. Frequency: 10-55-10Hz (1min.)

3. Direction: X, Y, Z

4. Duration: 2 Hrs/X, Y, Z |

|

| Climatic Test |

| Items |

Requirement |

Test Conditions / Test Methods |

| Low Temperature Storage |

Impedance change: Within± 20%

Without distinct damage in appearance

There should be no evidence of short or

open circuit

|

1. Temp: -40 ±2°C

2. Time: 1000±48 Hours

3. Component should be tested after 1hour at room temperature |

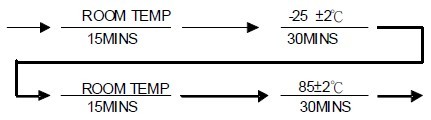

| Thermal Shock |

Total: 5 Cycles |

High Temperature Storage |

1. Temp: 85 ± 2°C

2. Time: 1000 ± 48 Hours

3. Component should be tested after 1hour at room temperature |

Humidity

High Temperature Load Life

Low Temperature Load Life |

1. Temp: 40 ± 2°C

2. R.H. : 90 ~ 95%

3. Time: 48 ±2 Hours

1. Temp: 85 ± 2°C

2. Time: 96 ± 12 Hours

3. Load: Allowed DC Current

1. Temp: -40 ± 2°C

2. Time: 96 ± 12 Hours

3. Load: Allowed DC Current |

|

| |

|

|

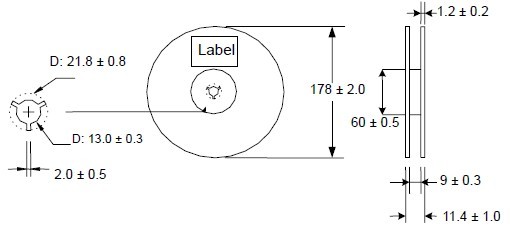

| ■Storage Temperature: 25±3°C; Humidity < 80%RH |

|

|

|

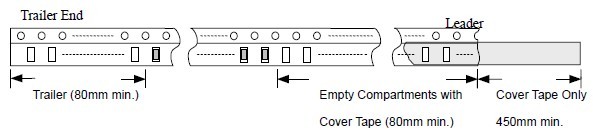

| Packaging Quantity |

Reel Specifications |

| Type |

EmbossedPlastic Tape(EA) |

| CMH05 |

2,000 |

| CMH06 |

2,000 |

|

|

|

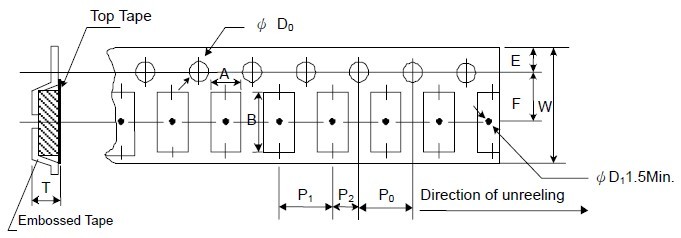

| Embossed Plastic Tape Specifications |

|

|

| Unit: mm |

| Type |

A |

B |

W |

E |

F |

P0 |

P1 |

P2 |

ΦD0 |

T |

| CMH05 |

1.40±0.10 |

2.55±0.05 |

8.0±0.20 |

1.75±0.10 |

3.5±0.10 |

4.00±0.10 |

4.00±0.10 |

2.00±0.10 |

1.50+0.10 |

1.35±0.10 |

| CMH06 |

1.90±0.10 |

3.50±0.05 |

8.0±0.20 |

1.75±0.10 |

3.5±0.10 |

4.00±0.10 |

4.00±0.10 |

2.00±0.10 |

1.50+0.10 |

2.10±0.10 |

|

|

|

|

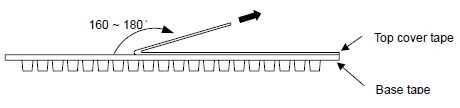

Peel-off Force

The force for tearing off cover tape is 0.05~0.69 (N) in the arrow direction at the following conditions:

Temperature: 5 ~ 35°C

Humidity: 45 ~ 85%

Atmospheric pressure: 860 ~ 1060hpa |

|

| |