| Multilayer Chip Inductor-CL Series |

| |

■Construction |

|

■Features

-A ceramic material construction for high frequency application up to 10GHz

-Tight tolerance physical dimensions(+/-0.05mm)

-Tight inductance tolerance and excellent Qvalue

-Available in three compact sizes of 0201,0402, 0603

■Applications

-High Frequency Application

-Cellular Phone

-EMI Countermeasure in High Frequency Circuits and Computer Communication etc.

-WLAN and RF module |

① |

Ceramic Material |

③ |

Inner Electrode(Ag) |

⑤ |

Direction Mark |

② |

Through Hole |

④ |

End-termination (Ag/Ni/Sn) |

|

|

■Dimensions

| Type |

Size

(Inch) |

L |

W |

T

|

A

(min./max.) |

Weight

(g)

1000pcs) |

| CL01 |

0201 |

0.6±0.03 |

0.3±0.03 |

0.33max. |

0.1/0.2 |

0.28 |

| CL02 |

0402 |

1.0±0.10 |

0.5±0.10 |

0.5±0.10 |

0.1/0.3 |

0.98 |

| CL03 |

0603 |

1.6±0.15 |

0.8±0.15 |

0.8±0.15 |

0.2/0.3 |

3.47 |

|

■Part Numbering

|

|

|

|

|

|

|

|

|

|

|

Dimensions |

01:0201

02:0402

03:0603 |

|

Inductance

Tolerance |

| J:±5%

K:±10%

S:±0.3nH |

|

Packaging

Code |

| T:Taping Reel |

|

Inductance |

1N0:1.0nH

39N:39nH

R10:100nH |

|

| |

|

|

|

|

| |

|

|

|

|

|

| |

■Electrical Specifications

CL01 Multilayer Chip Inductors Type

Inductance

(nH) |

Tolerance |

Quality

Factor

min. |

L/Q

Freq.

(MHz) |

Q (Typical)

Freq. (MHz) |

SRF

(GHz) min. |

DCR

(Ω) max. |

IDC

(mA) max. |

100 |

500 |

800 |

0.3 |

±0.3nH |

4 |

100 |

5 |

13 |

18 |

10 |

0.07 |

250 |

0.4 |

±0.3nH |

4 |

100 |

5 |

13 |

18 |

10 |

0.07 |

250 |

0.5 |

±0.3nH |

4 |

100 |

5 |

13 |

18 |

10 |

0.08 |

250 |

0.6 |

±0.3nH |

4 |

100 |

5 |

13 |

18 |

10 |

0.08 |

250 |

0.7 |

±0.3nH |

4 |

100 |

5 |

13 |

18 |

10 |

0.09 |

250 |

0.8 |

±0.3nH |

4 |

100 |

5 |

13 |

18 |

10 |

0.10 |

250 |

0.9 |

±0.3nH |

4 |

100 |

5 |

13 |

18 |

10 |

0.10 |

250 |

1 |

±0.3nH |

4 |

100 |

5 |

15 |

19 |

10 |

0.14 |

250 |

1.1 |

±0.3nH |

4 |

100 |

5 |

15 |

19 |

10 |

0.14 |

250 |

1.2 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

10 |

0.14 |

250 |

1.3 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

10 |

0.14 |

250 |

1.5 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

10 |

0.18 |

230 |

1.6 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

10 |

0.18 |

230 |

1.8 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

10 |

0.19 |

200 |

2 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

8.8 |

0.20 |

200 |

2.2 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

8.8 |

0.22 |

200 |

2.4 |

±0.3nH |

4 |

100 |

6 |

15 |

20 |

8.3 |

0.24 |

200 |

2.7 |

±0.3nH |

5 |

100 |

6 |

16 |

20 |

7.7 |

0.25 |

200 |

3 |

±0.3nH |

5 |

100 |

6 |

16 |

20 |

7.2 |

0.28 |

180 |

3.3 |

±0.3nH |

5 |

100 |

6 |

16 |

20 |

6.7 |

0.30 |

180 |

CL01 Multilayer Chip Inductors Type

Inductance

(nH) |

Tolerance |

Quality

Factor

min. |

L/Q

Freq.

(MHz) |

Q (Typical)

Freq. (MHz) |

SRF

(GHz) min. |

DCR

(Ω) max. |

IDC

(mA) max. |

100 |

500 |

800 |

3.6 |

±0.3nH |

5 |

100 |

6 |

16 |

20 |

6.4 |

0.30 |

170 |

3.9 |

±0.3nH |

5 |

100 |

7 |

16 |

20 |

6.0 |

0.30 |

170 |

4.3 |

±0.3nH |

5 |

100 |

7 |

16 |

20 |

5.7 |

0.40 |

150 |

4.7 |

±0.3nH |

5 |

100 |

7 |

16 |

20 |

5.3 |

0.40 |

150 |

5.1 |

±0.3nH |

5 |

100 |

7 |

16 |

20 |

5.0 |

0.40 |

150 |

5.6 |

±0.3nH |

5 |

100 |

7 |

16 |

20 |

4.2 |

0.40 |

150 |

6.2 |

±5% |

5 |

100 |

7 |

16 |

20 |

3.8 |

0.44 |

150 |

6.8 |

±5% |

5 |

100 |

7 |

16 |

20 |

3.5 |

0.50 |

150 |

7.5 |

±5% |

5 |

100 |

7 |

15 |

20 |

3.3 |

0.53 |

150 |

8.2 |

±5% |

5 |

100 |

7 |

15 |

20 |

3.2 |

0.55 |

150 |

9.1 |

±5% |

5 |

100 |

7 |

15 |

20 |

3.0 |

0.62 |

150 |

10 |

±5% |

5 |

100 |

7 |

15 |

19 |

2.8 |

0.65 |

150 |

12 |

±5% |

5 |

100 |

7 |

14 |

18 |

2.4 |

0.70 |

100 |

15 |

±5% |

5 |

100 |

7 |

14 |

18 |

2.2 |

0.80 |

100 |

18 |

±5% |

5 |

100 |

7 |

14 |

18 |

2.1 |

0.90 |

100 |

22 |

±5% |

5 |

100 |

7 |

14 |

18 |

1.8 |

1.20 |

100 |

27 |

±5% |

4 |

100 |

6 |

13 |

16 |

1.8 |

1.80 |

50 |

33 |

±5% |

4 |

100 |

6 |

12 |

14 |

1.7 |

2.10 |

50 |

39 |

±5% |

4 |

100 |

6 |

12 |

14 |

1.5 |

2.40 |

50 |

47 |

±5% |

4 |

100 |

6 |

11 |

13 |

1.3 |

2.80 |

50 |

56 |

±5% |

4 |

100 |

6 |

11 |

12 |

1.1 |

3.00 |

50 |

CL02 Multilayer Chip Inductors Type

Inductance

(nH) |

Tolerance |

Quality

Factor

min. |

L/Q

Freq.

(MHz) |

Q (Typical)

Freq. (MHz) |

SRF

(GHz) min. |

DCR

(Ω) max. |

IDC

(mA) max. |

| 100 |

500 |

800 |

900 |

1800 |

2000 |

2400 |

| 1 |

±0.3nH |

8 |

100 |

9 |

25 |

34 |

36 |

57 |

63 |

73 |

10.0 |

0.12 |

300 |

| 1.1 |

±0.3nH |

8 |

100 |

9 |

25 |

34 |

36 |

57 |

63 |

73 |

10.0 |

0.12 |

300 |

| 1.2 |

±0.3nH |

8 |

100 |

11 |

28 |

37 |

40 |

63 |

70 |

82 |

10.0 |

0.12 |

300 |

| 1.3 |

±0.3nH |

8 |

100 |

11 |

29 |

39 |

42 |

65 |

73 |

85 |

10.0 |

0.13 |

300 |

| 1.5 |

±0.3nH |

8 |

100 |

11 |

27 |

35 |

38 |

38 |

65 |

75 |

6.00 |

0.13 |

300 |

| 1.6 |

±0.3nH |

8 |

100 |

11 |

30 |

39 |

42 |

64 |

71 |

81 |

6.00 |

0.14 |

300 |

| 1.8 |

±0.3nH |

8 |

100 |

11 |

28 |

36 |

40 |

57 |

61 |

73 |

6.00 |

0.14 |

300 |

| 2 |

±0.3nH |

8 |

100 |

11 |

26 |

34 |

37 |

55 |

61 |

68 |

6.00 |

0.16 |

300 |

| 2.2 |

±0.3nH |

8 |

100 |

10 |

23 |

30 |

32 |

48 |

52 |

61 |

6.00 |

0.16 |

300 |

| 2.4 |

±0.3nH |

8 |

100 |

10 |

24 |

30 |

33 |

48 |

52 |

61 |

6.00 |

0.17 |

300 |

| 2.7 |

±0.3nH |

8 |

100 |

12 |

29 |

38 |

42 |

42 |

67 |

74 |

6.00 |

0.17 |

300 |

| 3 |

±0.3nH |

8 |

100 |

11 |

27 |

34 |

37 |

53 |

58 |

67 |

6.00 |

0.19 |

300 |

| 3.3 |

±0.3nH,±10% |

8 |

100 |

10 |

25 |

32 |

34 |

49 |

52 |

60 |

6.00 |

0.19 |

300 |

| 3.6 |

±0.3nH,±10% |

8 |

100 |

10 |

23 |

30 |

32 |

46 |

50 |

56 |

5.00 |

0.22 |

300 |

| 3.9 |

±0.3nH,±10% |

8 |

100 |

11 |

26 |

33 |

35 |

50 |

54 |

61 |

4.00 |

0.22 |

300 |

| 4.3 |

±0.3nH,±10% |

8 |

100 |

10 |

23 |

29 |

31 |

43 |

46 |

50 |

4.00 |

0.24 |

300 |

| 4.7 |

±0.3nH,±10% |

8 |

100 |

10 |

23 |

30 |

33 |

46 |

49 |

55 |

4.00 |

0.24 |

300 |

| 5.1 |

±0.3nH,±10% |

8 |

100 |

11 |

25 |

32 |

35 |

47 |

49 |

52 |

4.00 |

0.27 |

300 |

| 5.6 |

±0.3nH,±10% |

8 |

100 |

11 |

25 |

32 |

35 |

47 |

49 |

52 |

4.00 |

0.27 |

300 |

| 6.2 |

±0.3nH,±10% |

8 |

100 |

11 |

25 |

31 |

33 |

45 |

47 |

52 |

3.90 |

0.32 |

300 |

| 6.8 |

±5,±10% |

8 |

100 |

11 |

25 |

31 |

34 |

45 |

48 |

51 |

3.90 |

0.32 |

300 |

| 8.2 |

±5,±10% |

8 |

100 |

11 |

25 |

31 |

34 |

43 |

44 |

44 |

3.50 |

0.37 |

300 |

| 10 |

±5,±10% |

8 |

100 |

11 |

24 |

31 |

33 |

39 |

39 |

37 |

3.20 |

0.42 |

300 |

| 12 |

±5,±10% |

8 |

100 |

11 |

24 |

31 |

33 |

39 |

39 |

37 |

2.60 |

0.50 |

300 |

| 15 |

±5,±10% |

8 |

100 |

11 |

23 |

30 |

32 |

35 |

33 |

28 |

2.30 |

0.55 |

300 |

| 18 |

±5,±10% |

8 |

100 |

11 |

23 |

30 |

30 |

29 |

27 |

18 |

2.00 |

0.65 |

300 |

| 22 |

±5,±10% |

8 |

100 |

12 |

24 |

30 |

31 |

27 |

24 |

14 |

1.60 |

0.80 |

300 |

| 27 |

±5,±10% |

8 |

100 |

11 |

24 |

29 |

30 |

21 |

16 |

2 |

1.40 |

0.90 |

300 |

CL02 Multilayer Chip Inductors Type

Inductance

(nH) |

Tolerance |

Quality

Factor

min. |

L/Q

Freq.

(MHz) |

Q (Typical)

Freq. (MHz) |

SRF

(GHz) min. |

DCR

(Ω) max. |

IDC

(mA) max. |

100 |

500 |

800 |

900 |

1800 |

2000 |

2400 |

33 |

±5,±10% |

8 |

100 |

12 |

23 |

26 |

27 |

11 |

4 |

- |

1.20 |

1.00 |

200 |

39 |

±5,±10% |

8 |

100 |

11 |

22 |

24 |

24 |

1 |

- |

- |

1.10 |

1.20 |

200 |

47 |

±5,±10% |

8 |

100 |

11 |

21 |

23 |

23 |

- |

- |

- |

0.90 |

1.30 |

200 |

56 |

±5,±10% |

8 |

100 |

11 |

21 |

22 |

22 |

- |

- |

- |

0.75 |

1.40 |

200 |

68 |

±5,±10% |

8 |

100 |

12 |

21 |

21 |

19 |

- |

- |

- |

0.75 |

1.40 |

180 |

82 |

±5,±10% |

8 |

100 |

11 |

18 |

15 |

13 |

- |

- |

- |

0.60 |

1.60 |

150 |

100 |

±5,±10% |

8 |

100 |

11 |

19 |

15 |

12 |

- |

- |

- |

0.60 |

1.60 |

150 |

120 |

±5,±10% |

8 |

100 |

11 |

15 |

7 |

2 |

- |

- |

- |

0.60 |

1.60 |

150 |

150 |

±5,±10% |

8 |

100 |

12 |

18 |

9 |

4 |

- |

- |

- |

0.55 |

2.40 |

140 |

CL03 Multilayer Chip Inductors Type

Inductance

(nH) |

Inductance

Tolerance

(nH or %) |

Quality

Factor

min. |

L/Q

Freq.

(MHz) |

Q (Typical)

Freq. (MHz) |

SRF(GHz) min. |

DCR(Ω) max. |

IDC(mA) max. |

| 100 |

500 |

800 |

| 1 |

±0.3nH |

8 |

100 |

15 |

36 |

49 |

6.0 |

0.10 |

500 |

| 1.2 |

±0.3nH |

8 |

100 |

15 |

36 |

49 |

6.0 |

0.10 |

500 |

| 1.5 |

±0.3nH |

8 |

100 |

14 |

34 |

47 |

6.0 |

0.10 |

500 |

| 1.8 |

±0.3nH |

8 |

100 |

17 |

40 |

55 |

6.0 |

0.10 |

500 |

| 2.2 |

±0.3nH |

8 |

100 |

15 |

38 |

49 |

6.0 |

0.10 |

500 |

| 2.7 |

±0.3nH |

8 |

100 |

14 |

37 |

48 |

6.0 |

0.10 |

500 |

| 3.3 |

±0.3nH,±10% |

10 |

100 |

16 |

40 |

51 |

6.0 |

0.13 |

500 |

| 3.9 |

±0.3nH,±10% |

10 |

100 |

14 |

36 |

48 |

6.0 |

0.15 |

500 |

| 4.7 |

±0.3nH,±10% |

10 |

100 |

14 |

37 |

48 |

4.0 |

0.20 |

500 |

| 5.6 |

±0.3nH,±10% |

10 |

100 |

14 |

36 |

46 |

4.0 |

0.23 |

500 |

| 6.8 |

±5,±10% |

10 |

100 |

15 |

37 |

48 |

3.75 |

0.25 |

500 |

| 8.2 |

±5,±10% |

10 |

100 |

16 |

39 |

50 |

3.30 |

0.28 |

500 |

| 10 |

±5,±10% |

12 |

100 |

16 |

37 |

47 |

3.0 |

0.30 |

300 |

| 12 |

±5,±10% |

12 |

100 |

15 |

36 |

45 |

2.6 |

0.35 |

300 |

| 15 |

±5,±10% |

12 |

100 |

16 |

38 |

48 |

2.3 |

0.40 |

300 |

| 18 |

±5,±10% |

12 |

100 |

17 |

38 |

47 |

2.0 |

0.45 |

300 |

| 22 |

±5,±10% |

12 |

100 |

18 |

40 |

49 |

1.6 |

0.50 |

300 |

| 27 |

±5,±10% |

12 |

100 |

18 |

40 |

47 |

1.4 |

0.55 |

300 |

| 33 |

±5,±10% |

12 |

100 |

17 |

40 |

46 |

1.2 |

0.60 |

300 |

| 39 |

±5,±10% |

12 |

100 |

19 |

40 |

46 |

1.1 |

0.65 |

300 |

| 47 |

±5,±10% |

12 |

100 |

17 |

36 |

39 |

0.9 |

0.70 |

300 |

| 56 |

±5,±10% |

12 |

100 |

18 |

36 |

37 |

0.9 |

0.75 |

300 |

| 68 |

±5,±10% |

12 |

100 |

18 |

35 |

36 |

0.7 |

0.85 |

300 |

| 82 |

±5,±10% |

12 |

100 |

18 |

33 |

29 |

0.6 |

1.00 |

300 |

| 100 |

±5,±10% |

12 |

100 |

18 |

28 |

16 |

0.6 |

1.20 |

300 |

| 120 |

±5,±10% |

8 |

50 |

- |

- |

- |

0.5 |

2.30 |

250 |

| 150 |

±5,±10% |

8 |

50 |

- |

- |

- |

0.5 |

2.40 |

250 |

| 180 |

±5,±10% |

8 |

50 |

- |

- |

- |

0.4 |

2.70 |

250 |

| 220 |

±5,±10% |

8 |

50 |

- |

- |

- |

0.4 |

3.00 |

250 |

■Environmental Characteristics

Electrical Performance Test

Item |

Requirement |

TestCondition |

Inductance |

In within specified tolerance |

a. Temperature: 25±1°C

b. Relative Humidity: 45 to 85%RH

c. Atmospheric Pressure: 86 to 106kpa

d. Measuring equipment and fixture:

0201: HP4291B+Agilent16196C

0402: HP4291B+Agilent16193A

0603: HP4291B+Agilent16192A |

Q Value |

In accordance with electrical specification |

a. Temperature: 25±1°C

b. Relative Humidity: 45 to 85%RH

c. Atmospheric Pressure: 86 to 106kpa |

DC Resistance |

In accordance with electrical specification |

a. Temperature: 25±1°C

b. Relative Humidity: 45 to 85%RH

c. Atmospheric Pressure: 86 to 106kpa

d. Measuring equipment: HP 4338 |

Temperature

Characteristics |

Within specified tolerance |

a. Temperature range: -30 to﹢85°C

b. Reference temperature: 25°C |

Mechanical Characteristies Test

Item |

Requirement |

TestCondition |

Bending Strength |

No mechanical damage shall be observed |

Solder the chip to test jig then apply a force in the direction shown in below. The soldering shall be done with the reflow method and shall be conducted with care so that the soldering is uniform and free of defects such as heat shock. |

|

|

Solderability |

More than 75% of the terminal electrode part shall be covered with fresh solder |

Immerse a test sample into a methanol solution containing rosin,preheat it at 150 to 180°C for 3 to 5 seconds and immerse into molten solder of 245±5°C for 5±0.5 seconds. |

Resistance

to Soldering Heat |

No visible damage |

Immerse a test sample into a methanol solution containing resin, preheat it at 150 to 180°C for 2 to 3 minutes and immerse into molten solder of 260±5°C for 10±0.5 seconds so that both terminal electrodes are completely submerged. |

Appearance |

In accordance with specification |

Inductors shall be visually inspected for visible evidence of defect |

Dimension |

In accordance with dimension specification |

Dimension shall be measured with caliper or micrometer |

Climatic Test

Item |

Requirement |

TestCondition |

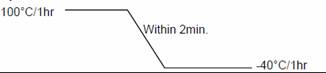

Thermal Shock |

No visible damage

Inductance variation within 10%

Q variation within 20% |

Solder a test sample to printed circuit board, and conduct 100

cycles of test under the conditions shown as below.

Cycle:

|

|

Thermal Shock

High Humidity State Life |

No visible damage

Inductance variation within 10%

Q variation within 20% |

Keep a test sample in an atmosphere with a temperature of

70±2°C, 90~95%RH for 500±12 hours. After the test, keep the

test sample at a normal temperature for 1 to 2 hours, and then

carry out measurement. |

High Humidity Load Life |

No visible damage

Inductance variation within 10%

Q variation within 20% |

Solder a test sample to printed circuit board then keep the test

sample in an atmosphere with a temperature of 70±2°C,

90~95%RH for 500±12 hours while supplying the rated current.

After the test, keep the test sample at a normal temperature for 1

to 2 hours, and then carry out measurement. |

High Temperature State Life |

No visible damage

Inductance variation within 10%

Q variation within 20% |

Keep a test sample in an atmosphere with a temperature of

100±2°C for 500±12 hours. After the test, keep the test sample

at a normal temperature for 1 to 2 hours, and then carry out

measurement. |

High Temperature Load |

No visible damage

Inductance variation within 10%

Q variation within 20% |

Solder a test sample to printed circuit board then keep the test

sample in an atmosphere with a temperature of 100±2°C for

500±12 hours while supplying the rated current. After the test,

keep the test sample at a normal temperature for 1 to 2 hours,

and then carry out measurement. |

■Storage Temperature: 25±3°C; Humidity 80%RH

■Packaging

|